Important dates:

| 01.02.2015 | Registration start |

| 01.06.2015 | Deadline for Abstract Submission |

| 01.07.2015 | Deadline for Date of Acceptance |

| 31.07.2015 | Early Registration Deadline |

| 20.08.2015 | Deadline for camera ready Manuscript Submission |

| 01.09.2015 | Deadline for Registration |

| 27.09. - 01.10.2015:ISTP 26 | |

Univ.-Prof. Dipl.-Ing. Dr.techn. Johannes Khinast

Multiphase Modeling and Large-Scale Simulations on GPU Platforms

Prof. Johannes Khinast

Institute for Process and Particle Engineering, TU Graz

Research Center Pharmaceutical Engineering

Inffeldg. 13

Tel: +43 (0) 316 873 30403

Email: khinast@tugraz.at

Abstract

In this talk first a brief introduction to the current state of multiphase modeling and simulation is given. Then, the need for the development of robust and reliable multi-scale models is highlighted to replace trial and error and extensive experimentation.

In this context, various modeling approaches are presented, including the discrete element method (DEM), computational fluid dynamics (CFD), the coupling the combination of CFD and DEM as well as molecular simulations. Processes that are highlighted are the coating of particles, fluid-bed operations, powder mixing, gassed stirred tank reactors and the leaching from packing materials.

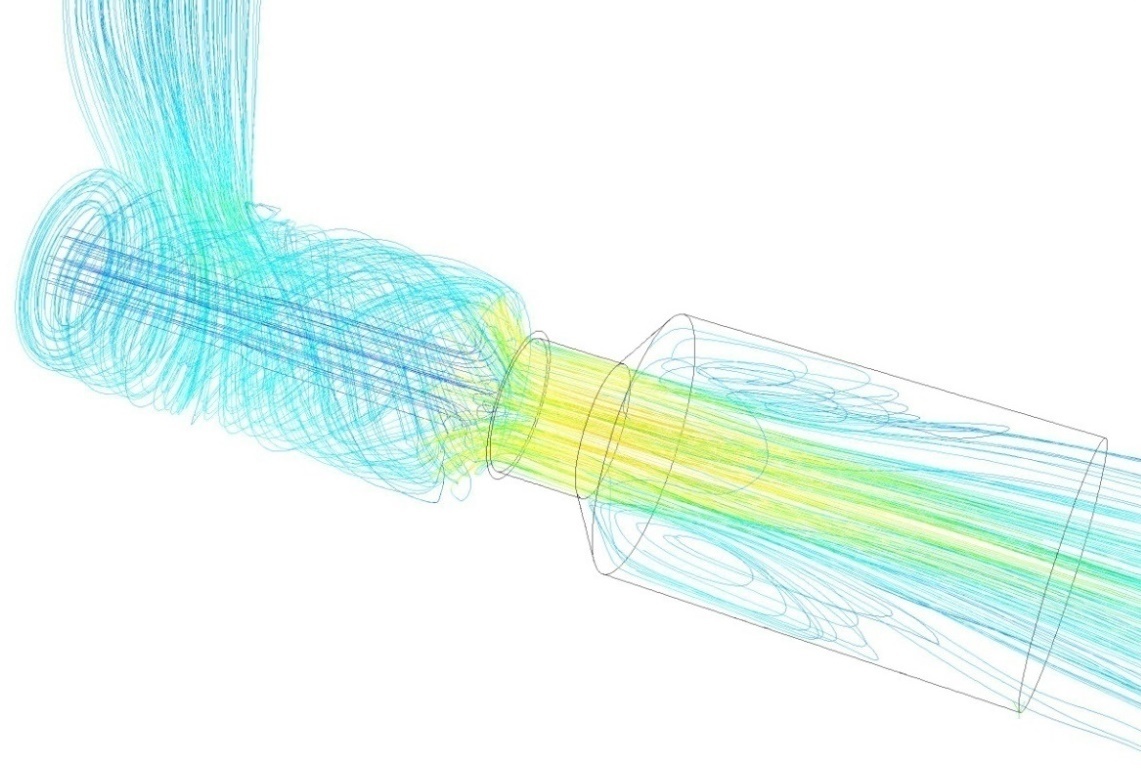

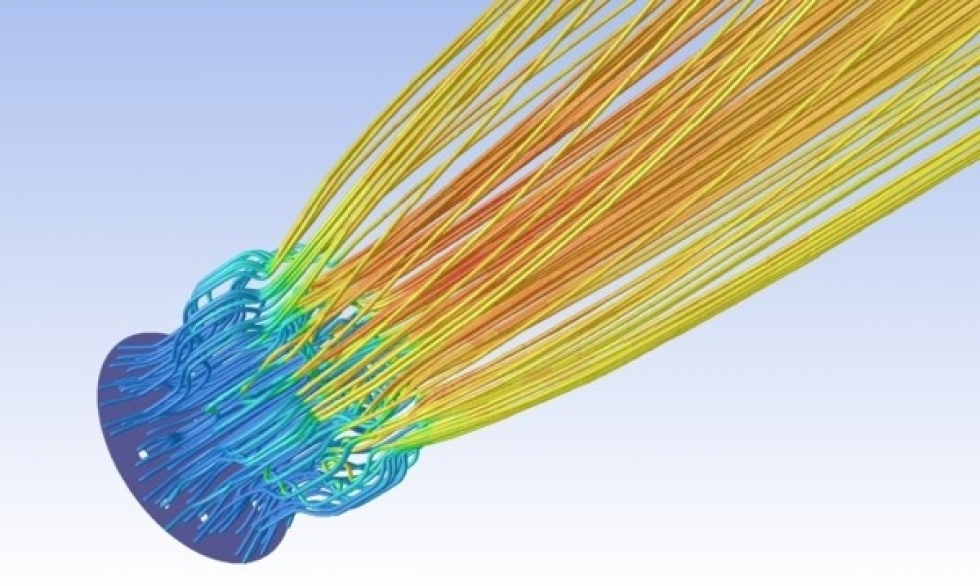

In the field of fluid bed modeling we use the Compute Unified Device Architecture (CUDA) technology that – for example – can be used to perform massively-parallel DEM-simulations with several million particles on a single desk-side Graphics Processing Unit (GPU). Fluidized system simulations with up to 30 million particles are shown in the Figure [1].

Figure: Snapshot of the triple spout-fluidization regimes at t=1.0s with 25.000.000 of particles of d=0.48mm [1]

|

In addition, our efforts in the in-silico development of coating process in drum coaters are presented. Here we have recently developed new methods for implementing efficient spray detection in DEM simulations [2]. The spray modeling was performed while the main DEM simulation was running and after the simulation using saved data. Lastly, studies of the mixing of granular materials, i.e., powders, and the wetting of such systems are presented as a prerequisite for the first-principles modeling of high-shear granulators [3]. Finally, our recent work in the modeling of granular systems (blending, extrusion), gassed stirred tanks (bio-reactors) and molecular modeling (leaching) is presented in this talk. |

References

- Jajcevic D., Radeke C. and J.G. Khinast (2013), Large-scale CFD-DEM Simulations of Fluidized Granular Systems, Chemical Engineering Science 98, p. 298-310

- Toschkoff G., Just S., Funke A., Djuric D., Knop K., Kleinebudde P. Scharrer G. and J.G. Khinast (2013), Spray Models for Discrete Element Simulations of Particle Coating Processes, Chemical Engineering Science, Vol. 101, p. 603-614

- Radeke, J. G. Khinast, Modeling of Sprayed Agitated Systems”, (2013), unpublished manuscript